Over the past few years, and especially through the beginning of this century, 3D printing has revolutionized the way conventional manufacturing and 3D modeling are done. Now with a 3D printer, you can get your 3D printed parts in a much shorter time frame than previously thought. But what is the cost of this technology, and is it worth it in the end?

Quantity

When we talk about the number of products, we find that it is by far cheaper to use 3D printing services to produce fewer parts. Instances when this could be necessary are replicas, replacement parts, and prototypes, including those with interactive designs.

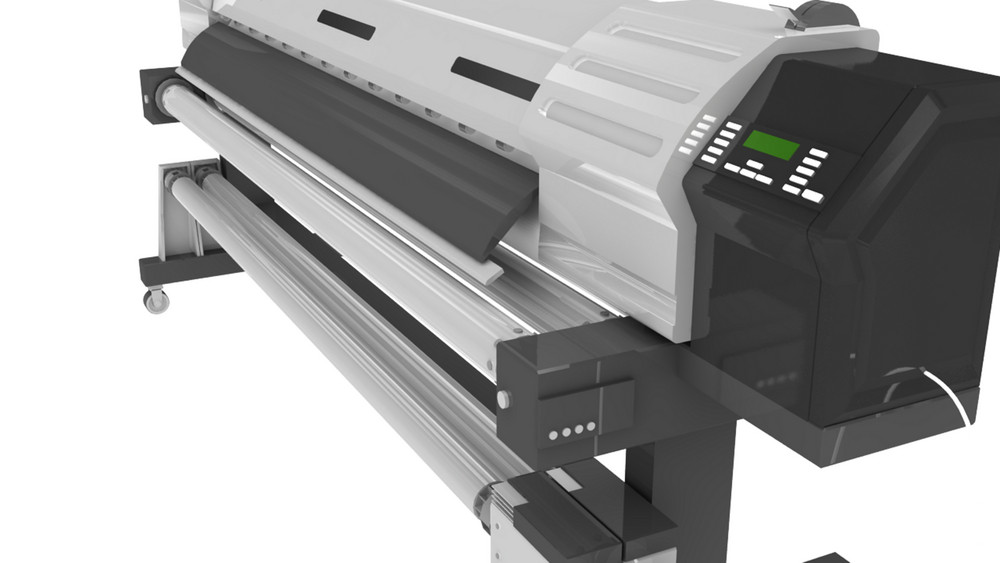

With technology like the 5200 3D printer, industrial manufacturing is more convenient than ever. The build volume is huge, the quality of the products produced is high, and the precision of what you’re creating is impeccable.

3D printing services are revolutionary, even when you consider some shortcomings like increasing expense with increasing quantity. It is still a very useful tool for actualizing creative and innovative ideas for many artists. If you are wondering how cost-effective 3D printing services are, read on to see some of the situations in which you can save by choosing 3D manufacturing over other methods like injection mold manufacturing.

Manufacturing Prototypes

Prototyping is the most popular application of 3D printing in the aerospace industry at 72%. This is followed by repair at 44%, research, and development at 43%, and finally production parts at 39%. This data from Jabil (A Survey of Aerospace and Defense OEMs) done in May 2019 shows just how popular 3D printing is.

For the creation of prototypes, 3D printing is cheaper than mold manufacturing because there is no mold tooling necessary. Generally, prototypes will be cost-effective and fast to produce with 3D printing, after which other manufacturing methods may be used. This is after all possible corrections have been made to the part in question and the final product has been decided on, to save on wastage of material.

Assembled Parts

With 3D printing, you can save a lot of time and material by printing fully assembled parts. This beats other manufacturing processes whereby you have to print each part separately and then assemble them post-production.

Creating New Designs

When coming up with a new product that has never been created before, 3D printing services will be a great option. This is because there will be lowered costs accompanied by more flexibility to change the design as necessary. Other manufacturing methods will be too expensive and offer little opportunity to change designs, often making you have to stick with a design close to what you envisioned, rather than getting exactly what you wanted.

Making Complex Designs

If you need to manufacture parts that have complicated details and design, 3D printing provides a great solution. Parts with many features will be fast and easy to produce in this way, keeping waste to a minimum and making the best use of raw material.

Advanced designs can easily be printed with 3D printers. It is more cost-effective to print them than it is to procure from manufacturers. This is because making molds is an expensive process, so making complex molds is an even harder task. The expense from tooling the mold is the cost that is transferred to the end product made, sometimes leading to a prohibitive cost.

A lot is possible with this method of manufacturing, more than was possible some years back, and even more breakthroughs will follow. For quotes of prospective cost of your manufacturing needs, make sure to consult before you begin the process.